One of the challenges of space development (see above) is the cost of launching Earth-derived materials for use in space. Space settlements could be built much more cheaply if we could obtain our raw materials from asteroids (it is cheap to launch things from asteroids). The difficulty is that then products would have to be fabricated in space. That wouldn't be easy - on Earth, we need heavy, special-purpose machinery to shape materials. It would be just too expensive to try to duplicate Earth's industrial base off planet! If we could build up virtually any shape with just one lightweight machine, then extraterrestrial materials could be used to greatly lower the cost of space development.

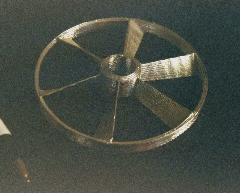

In 1989 I founded a company named Incre and began work on a machine that could build a wide variety of shapes from metal (using first tin, then aluminum). It soon became clear that there would be down-to-Earth uses for such a machine in rapid prototyping applications. The technique would also make feasible the manufacture of objects with complicated internal voids, including lightweight, strong structural parts that mimic bone. The objects shown here were all made by one lightweight, versatile machine. It builds up shapes one layer at a time by ejecting fine droplets of molten metal in carefully controlled locations.

In 1989 I founded a company named Incre and began work on a machine that could build a wide variety of shapes from metal (using first tin, then aluminum). It soon became clear that there would be down-to-Earth uses for such a machine in rapid prototyping applications. The technique would also make feasible the manufacture of objects with complicated internal voids, including lightweight, strong structural parts that mimic bone. The objects shown here were all made by one lightweight, versatile machine. It builds up shapes one layer at a time by ejecting fine droplets of molten metal in carefully controlled locations.

Ten years of work led to three patents but not to a commercially viable device. Still, I believe that this or a related approach will revolutionize small-scale manufacturing.

Ten years of work led to three patents but not to a commercially viable device. Still, I believe that this or a related approach will revolutionize small-scale manufacturing.